If fatty alcohols containing 16 or more carbon atoms per molecule are used in the synthesis of alkyl polyglycosides, the resulting product is soluble in water only at very low concentrations, typically DP of 1.2 to 2. They are hereinafter referred to as water-insoluble alkyl polyglycosides.Among these alkyl polyglycosides, the nonpolar characteristics are dominant because of the long alkyl chain.These are not used as surfactants but are primarily used as emulsifiers in cosmetic formulations.

The observed reaction of glucose with dodecanols/tetradecanols is largely applicable to the synthesis of water-insoluble alkyl polyglycosides, such as cetyl/octadecyl polyglycosides.Acid catalyzed reactions take place at similar temperatures, pressures, and molar ratios between feedstocks. However, because of their low solubility, these products are more difficult to refine and bleach as water-based pastes. It is important to produce the products with low content and light color directly after the reaction step, thus avoiding further treatment.

The most important unwanted by-product is polyglucose.It is yellowish-brown and thus significantly deteriorates color. In addition, the presence of high concentrations of polyglucose makes it difficult to concentrate the reaction mixture by distillation, because polyglucose tends to decompose very rapidly as temperatures rise. This ultimately also impair the performance properties.

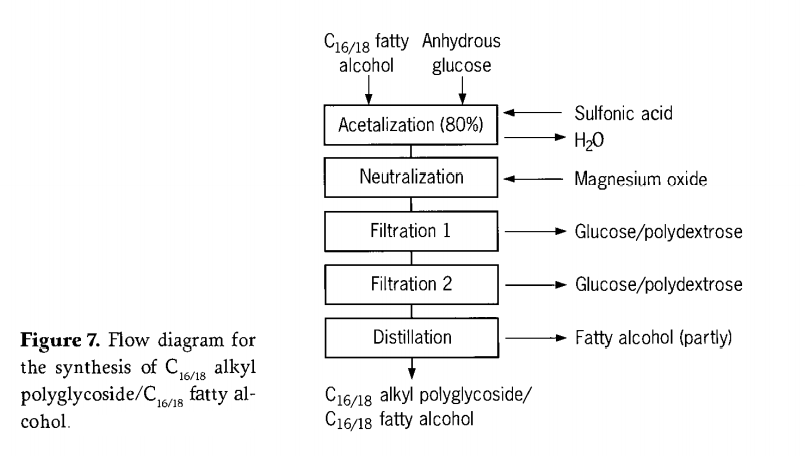

Since the rate of polydextrose formation increases significantly near the end of the reaction, the reaction terminates prematurely at about 80% glucose conversion by lowering the temperature and neutralizing the catalyst. To ensure uniform and reproducible product quality, online analysis is used to accurately track the transformation. At termination, the unreacted glucose is present as a suspended solid and can be easily removed by subsequent filtration. After the removal of glucose, the product contains approximately 1-2q of polydextrose, which is emulsified in very fine droplets. By selecting the appropriate filter aid, polydextrose can be completely removed in the second filtration step.

A substantially glycose and polydextrose-free product containing 15 to 30% of long-chain (C 16/18) alkyl polyglycosides and 85 to 70% of fatty alcohol ( C16/18-OH) is obtained by this process. Since the product has an elevated melting point, it is normally marketed as a solid in the form of flakes or pellets.

High levels of long-chain alcohols are acceptable because many cosmetic lotions contain large amounts of the same alcohol. Therefore, alkyl polyglycosides can be directly used as alkyl polyglycosides/fatty alcohols.

The fairly recent types of water-insoluble alkyl polyglycosides contain about 500% alkyl polyglycosides and 500% fatty alcohols.In this case, a portion of the fatty alcohol is removed by vacuum distillation and the thermal decomposition is suppressed by keeping the temperature and residence time as low as possible. (Figure 7) This concentrated product type greatly expands the range of applications of water-insoluble alkyl polyglycosides.

Post time: Oct-18-2020